Brain Industries is now the exclusive supplier of Visyload, a money saving, load sensing washer for rock bolts, other bolts and threaded anchors.

Managing Director, Phil Hempenstall, said the washer lets you know, at a glance, the working load limit on a rock bolt or threaded anchor.

Visyload is a game-changer for underground mines and tunnels

Mr Hempenstall said Visyload is a game changer because no longer do you need a specialist geotechnician to assess the rock bolt or threaded anchor.

He said when you consider how many rock bolts and threaded anchors are in mines and tunnels, Visyload equates to big savings in time and money.

“Any competent person can install it and verify the correct bolt pull out strength,” Mr Hempenstall said.

“Customers not only save money by not paying specialist assessors, they also avoid staff downtime waiting for an assessor to arrive,” he said.

“Staff downtime is a huge cost which Visyload helps to take out of the equation.”

How does Visyload work?

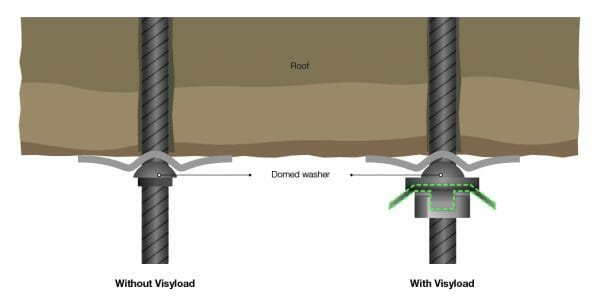

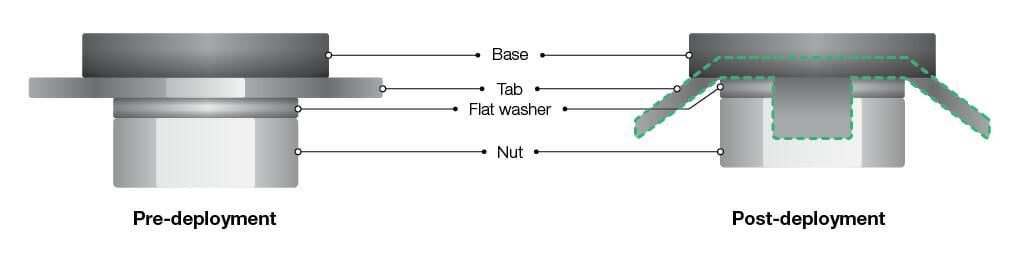

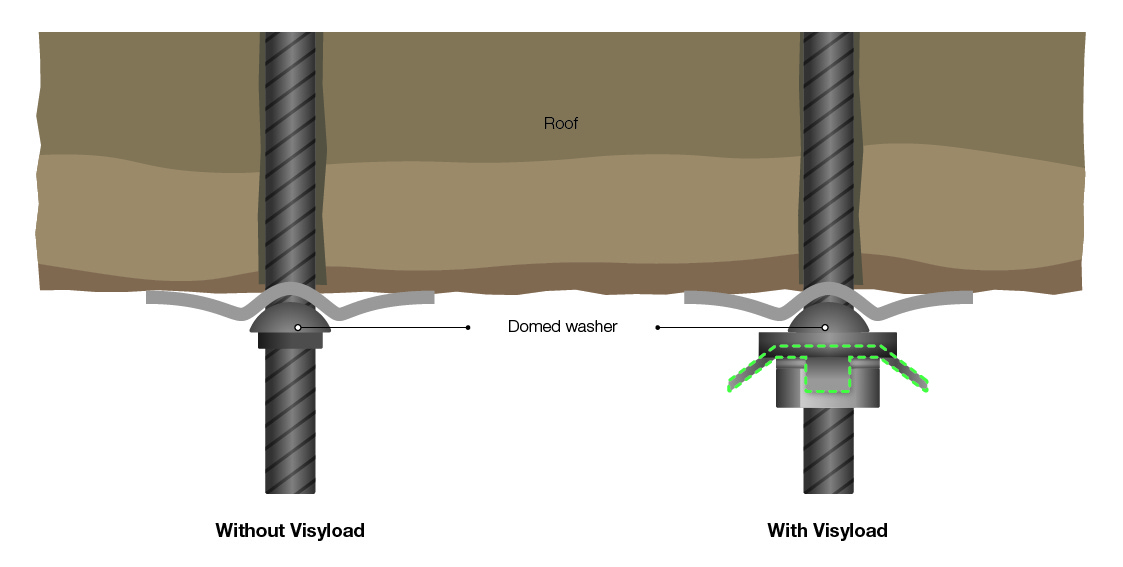

Mr Hempenstall said Visyload is simple to use. He said tits tabs curl down when they deploy. This indicates the applied tension or torque to confirm the rock bolt’s or threaded anchor’s safe working load limit.

There are different models for different weights. The three tab washer is for weights of three tonnes. The four tab detects six tonnes and the six tab is for up to eight tonnes. Visyload is developing models for other weight limits.

Brain Industries Managing Director, Gillian Summers, said Visyload is a welcome addition to the products it supplies to the mining, tunnelling and other industries. Ms Summers said 2,000 of the washers were trialled at an underground mine in NSW with overwhelmingly positive results.

She said Visyload is a quality product manufactured in Australia by an Australian owned company.

“Visyload has been performance tested and accredited in a NATA certified laboratory,” Ms Summers said.

“Visyload is made with heat certified steel and other raw materials under a strict ISO9001 accredited quality system,” she said.

She said as well as the huge potential savings in time and money, Visyload brings risk management and WHS benefits.

“Being instantly certain whether a rock bolt can safely suspend a load reduces the risk of workplace injuries in underground mines, tunnels and other industries that use rock bolts.”

What is a rock bolt?

A rock bolt is a long anchor bolt, for stabilising rock excavations. Rock bolts are in tunnels or rock cuts and in underground mines. They transfer load from the unstable exterior to the confined (and much stronger) interior of the rock mass.

A steel rod goes inside a hole in the the roof or walls of a rock formation to support the roof or sides of the cavity. Rock bolt reinforcement is simple, quick to apply and is relatively inexpensive. In Australian underground mines it is mandatory to assess each rock bolt.

More information or orders

For more information download the brochure here. To order Visyload call Brain Industries on +61 2 4969 2111 or email admin@brainindustries.com.au